Description

No joke about this being the most tuning stable and reliable dulcimer on the planet! It is true. The Finch Chromatics just stay in tune… and sound great, too. This is Chris’ all time favorite dulcimer. He only has to tweak the tuning maybe once a month. You can take it places and it’ll be in tune when you get there. Truly amazing! When we start heating in the fall it will go flat just a little. When summer comes, it will go sharp just a little, maybe 1/4 step. Those are the only major changes. More below on how we achieve this.

Features

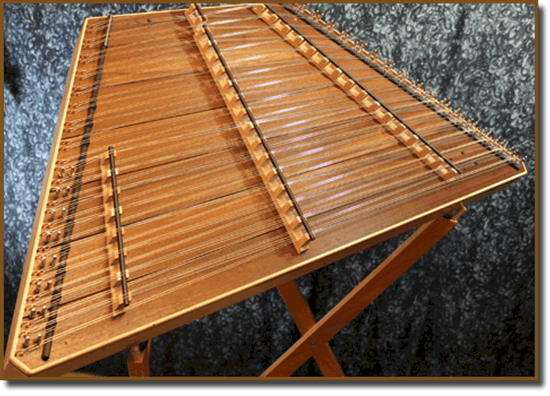

- 17/16/8

- Locally produced Air Dried Walnut top

- Curly Maple bindings, Hard Maple sides, Walnut bridges, and back ply

- Plays well in dry or humid conditions

- Stable, reliable, stays in tune

- Sound holes in the back

- Comes with case, stand, hammers, and tuning wrench

No Cracks or Warps

The trouble with solid wood is it shrinks or swells across the grain with changes in humidity in the environment. It can move a lot. The rule of thumb in woodworking is not to glue wood cross grain over 8 inches wide. But we routinely do it in the hammered dulcimer world, gluing tops as wide as 24 inches to maple pin blocks. It is asking for trouble, but we all do it. If the top is not totally dry when glued to the frame, and it shrinks in winter, it can crack. If it is dry, but the humidity goes way up, it will swell and put stress on the overall instrument.

The construction of the top for the Finch model is a completely new and novel way to eliminate this problem. They are composed of 7 individual narrow boards joined by tight fitting tongue and groove joints which are not glued. This allows each individual board to shrink or swell as it needs without causing problems.

No more cracks, no warps, no having to keep your dulcimer in a specially humidified environment in the winter or you void your warranty, no worries at all. Just play it and enjoy it. We believe this is the way solid wood top hammered dulcimers should be built. It works great! We have tested them, and they will take almost any environment and just sound good. No special care necessary. Sound holes all need to be in the back on these. Cutting sound holes on the top would compromise the structure.

Most other builders tell you to keep your dulcimer humidified in the winter because of the wood shrinkage problem. We recommend that you don’t do that for our dulcimers. If you are humidifying your home for comfort, that’s fine, but don’t do it for the dulcimer’s sake. We believe you’ll struggle with tuning a lot less if the dulcimer is allowed to just adapt to the environment.

Made with Locally Sourced Air Dried Walnut

For solid one board tops, builders are pretty much trapped with some version of mahogany or other, or a softwood like spruce because they are the most stable. But with our new system it is now possible to make dulcimers from many different woods. We tried a bunch, they all sounded good, but some are better. Air Dried Walnut is just magical, with rich full tone and amazing tuning stability!

A word on Walnut. Commercial producers kiln dry their walnut and steam it in the process. This is to drive some of the color from the heartwood out into the normally white sapwood so they get a better yield. But it also muddies the color. Kiln dries walnut is a uniform milk chocolate brown, but Air Dried Walnut is vibrant, more red and with streaks of color sometimes almost purple. Kiln dried walnut will get lighter with age, but Air Dried Walnut gets darker and richer with age.

Air Dried Walnut is also harder and sounds better. So kiln drying walnut is a good way to ruin some of the world’s most beautiful material. Air Dried Walnut can’t be just ordered from a hardwood supplier, but fortunately we live in Walnut Country and are able to get it locally from a variety of sources. So this is indeed special material.

Availability: We are a small Mom and Pop enterprise, and can’t have everything we make in stock all the time. We should have all of the accessories and small items all of the time. We also try to keep natural

Availability: We are a small Mom and Pop enterprise, and can’t have everything we make in stock all the time. We should have all of the accessories and small items all of the time. We also try to keep natural

Jason Shover –

Before even writing this review, I want to say feel free to contact me on facebook messenger (Jason Shover) with any questions and to confirm this review. I live in Pennsylvania where temp swings can be drastic. I bought this dulcimer in February, tuned it. Since then it has endured a trip to our family cabin kept at 48 degrees then home again where Temps hit 80! Still in perfect tune! Earthy, woody tone…the Finch doesn’t have that overbearing, eternal metalic sustain of too many other hammered dulcimers. Thanks so much for being a true artist of your craft!

Songbird Dulcimers –

Thank you so much, Jason!